Contact Our Experts

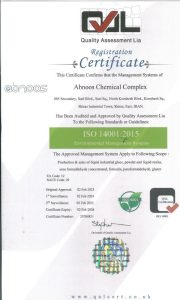

Abnoos Chemical Complex was established in 2016 as a specialized manufacturer of liquid industrial adhesives and impregnating resins. Founded by a team of skilled engineers and specialists, the company was built upon the transfer of essential technical knowledge to address the needs of manufacturing units and industries producing chipboard, MDF, and cellulose-based products.

Contact Our Experts

In today’s complex world, we help you restore and transform your business by providing innovative and sustainable solutions.

With over several years of experience in the field of international trade, Abnoos Company provides professional services in the fields of import, export and business consulting. Using accurate market analysis, we have been able to provide the best solutions to reduce costs and accelerate business processes. Our experienced and specialized team, with a deep understanding of international and customs regulations, helps you to operate more successfully in the complex world of global trade.

Explore our company’s products along with detailed descriptions.

We have always strived to provide you with the best services.

Formaldehyde is the simplest known aldehyde, first identified in 1859 by Butlerov. It is characterized by its high reactivity and its important role as an intermediate molecule in many chemical reactions. Formaldehyde is used in various forms, including anhydrous monomer solution, polymers, and their derivatives, although the anhydrous monomer itself is not commercially available. It is relatively stable at temperatures between 80 and 100 °C but gradually polymerizes at lower temperatures. The presence of metals such as platinum, copper, chromium, and aluminum can catalyze its conversion into substances like methanol, methyl formate, formic acid, carbon dioxide, and methane. Very small amounts of formaldehyde are also present in urban atmospheres, where it rapidly undergoes photochemical oxidation, with a half-life of about 30 to 35 minutes, ultimately converting to carbon dioxide.

Melamine–formaldehyde impregnation resin is produced through the condensation reaction of melamine and formaldehyde. Specialized papers such as décor paper, overlay paper, and backing paper are impregnated with urea–formaldehyde and melamine–formaldehyde resins and used in the production of decorative wood panels. Urea–formaldehyde overlay resins undergo hydrolysis when exposed to moisture or water and have lower heat resistance. Therefore, they are commonly used in combination with melamine–formaldehyde resins. In some cases, urea–formaldehyde impregnation resin is first applied to fill the pores of the paper, followed by a top layer of melamine–formaldehyde impregnation resin.

Urea–formaldehyde impregnation resin is produced through the condensation reaction of urea and formaldehyde. Specialized papers such as décor paper, overlay paper, and backing paper are impregnated with urea–formaldehyde and melamine–formaldehyde resins for use in manufacturing decorative wood panels. Urea–formaldehyde overlay resins are susceptible to hydrolysis when exposed to moisture or water and possess lower heat resistance. Therefore, they are often used in combination with melamine–formaldehyde resins. In certain applications, urea–formaldehyde impregnation resin is first applied to fill the pores of the paper, followed by a coating layer of melamine–formaldehyde impregnation resin.

Dried urea–formaldehyde resin in powder form is a cost‑effective solution for producing feed pellets. This material is used to enhance the stability and water durability of the pellets. It can also be used in poultry and cattle feed to reduce dust formation and increase hardness. For use, add it directly to the feed mixer just before the pelleting or extrusion process. The dosage depends on the feed formulation and processing conditions.

Urea–formaldehyde resins are among the most important amino resins, widely produced from the combination of urea and formaldehyde due to their affordable cost, high reactivity, and excellent performance. In cases where wood products are manufactured intermittently and there is a need for long-term adhesive storage, powdered urea–formaldehyde adhesive is used instead of the liquid form. The transportation cost of powdered urea–formaldehyde adhesive is lower than that of its liquid form.

Glazer is a type of melamine–formaldehyde powder used for glazing melamine tableware. Liquid melamine–formaldehyde resin is converted into a powdered product using a spray dryer. A thin layer of glazer on melamine tableware prevents direct contact between melamine and food while creating a glossy coating on the surface. Tableware coated with this product becomes resistant to abrasion, detergent absorption, and moisture. This resin is also used for impregnating melamine décor paper (decal paper) after being dissolved in water.

Paraformaldehyde is the solid form of liquid formaldehyde, produced through the polymerization of 8–100 molecules of formaldehyde. As a concentrated form of formaldehyde, paraformaldehyde shares similar properties but offers a wider range of applications.

receive consultation, please complete the form below.